We’ve almost finished excavating the rear for our foundation drain. It did collapse in parts so I cleared that up and spent some money on some semi-decent shuttering to hold back the soil. We’re away at the moment but we couldn’t have started to fill the trench in anyway as the lime paster needs to cure for about a month.

So before the drainage pipes go in and we start to fill etc we have to consider what treatment we should apply to the wall. If the wall had been Portland based then we would have added some sort of membrane to keep the moisture from permeating into the wall, this could have been something we painted on combined with a plastic membrane. Because our lime walls need to remain porous the former option was out leaving us with the membrane. I was going to use our leftover Stego 10 mil vapour barrier plastic which is pretty tough, however after further investigation into foundation drains I came across a product called dimple board. (Note: I had been previously searching the web for French drains whilst in reality ours is a foundation drain).

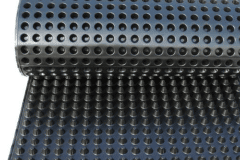

The dimple board seemed to be the perfect solution and the reason it’s called dimple board is because it has 5/16″ dimples which provide an important service. The dimples protrude towards the wall and leave an air gap for any moisture against the wall to trickle down by gravity. These dimples can withstand the pressure of the soil so remain intact when the trench has been filled. If we had gone with a flat plastic membrane, that would have been pressed flat against the wall and any water behind it would have been held there due to surface tensioning things and wouldn’t have drained.

We got our dimple board and accessories from the nice people at DIY Basement Solutions who provided one stop shopping for the system plus the product looked to be of good quality and was available in a variety of widths.

So next steps on our return is to:

- Do a bit more digging to achieve the 1/8″ fall per foot for the pipe

- Lay down a geotextile membrane*

- Add a couple of inches of gravel

- Lay the pipe and check the levels etc and then fill around the pipe with gravel

- Attach dimple board to wall and wrap over footings

* The geotextile membrane surrounds the gravel and the pipe and it’s purpose, especially in sandy soils like we have, is to keep the sand out of the gravel which would slow the drainage of water through the gravel. Once all that is done we’d attach the dimple board to the wall, bending it over the footings and then start to fill up the trench with gravel.

One thing that might cause a problem is around the corner we have the old cast iron sewer pipe and it seems to be right in the way of where we want the foundation drain to be. When the plumbers removed a section of this a few years ago the pipe wall was about 1/2″ thick so that will be a challenge to cut off.