If you remember last year we had a concrete pour that didn’t go so well. Al Riozzi (AJR Masonry) admitted it wasn’t acceptable but wouldn’t fix it. We could have left it as it was but I felt that it might cause problems in the long term and if we were going to level it, now was the time.

Unfortunately for us we couldn’t fix it until now as self-leveling concrete can’t be used when it’s cold. It’s now warm enough, so today we took a stab at it. I wouldn’t say it’s a hard job but you have to be prepared. I’ve been watching youtube video and reading up about it since last year, but I was still a little nervous as most of these products have a very short flow time (10 minutes in our case). Luckily it went well, I had all the tools, buckets, product lined up etc. but most importantly I had a great team of volunteers helping me, so a big shout out to Joe, Deborah, Rob and Aimee. Every one was assigned a different task and everyone preformed flawlessly.

Music was requested by Joe.

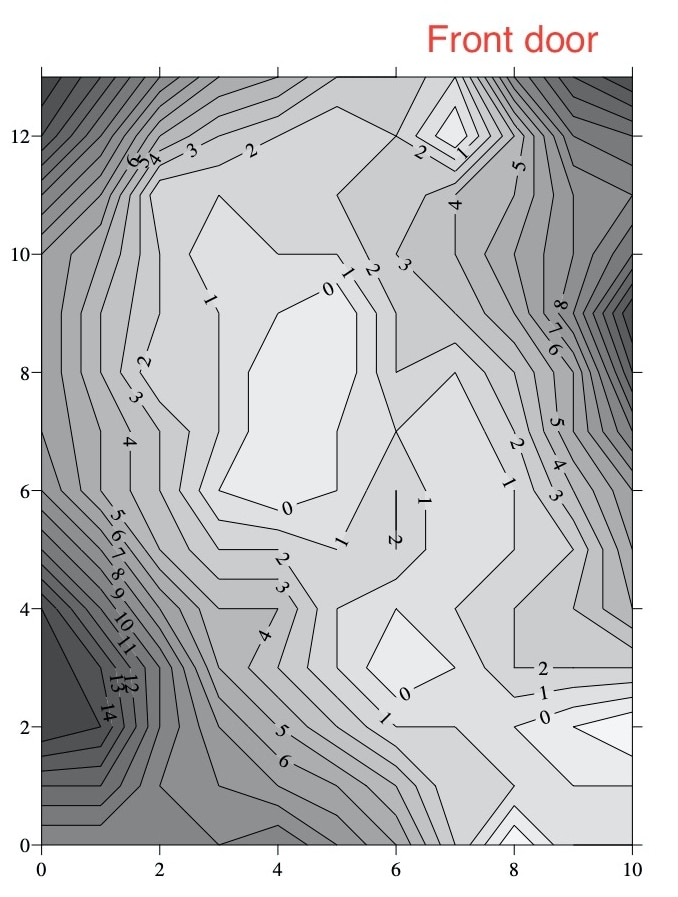

My goal was to fix the floor in two passes, first pass was to fill in all the deep areas (shown as the darker areas in he contour map) and the second pass was to cover the complete floor with a final skim coat, re-priming between coats. My only mistake was not ordering enough product. I ordered 17, 40lb. bags of Henry 565 ($40 a bag, so not cheap) and I thought that would be enough – no where near and I think it covered about half of the first pass. I just ordered another 46 bags so hopefully that will be enough. Thanks for picking it up Joe 🙂

Even though we didn’t get as much done today as I expected it was a great trial run and everyone now knows what their tasks are and are willing to help us again. Incidentally all the mixing and product were laid down in under an hour, which was pretty quick. I think we all felt we could have easily have managed twice or three times that amount.

Returning to examine the floor on Sunday we noticed some wrinkling in some areas. Not sure what caused this but will ask the manufactures if they know. Second picture shows how it should look, nice and smooth.

Thanks again team!!!

One more box almost ticketed, and then it’s onwards and upwards.

Yes indeed and hopefully we can finish it off over the coming weekends 🙂

The wrinkling is odd. Reaction with the concrete ? But primer should have taken care or that

if you have deep patches you can add aggregate ( pea gravel ) but leave enough room for a final skim coat. You don’t want any protrusions. Well, not at our age.

Going to talk to Ardex today and hopefully they will have suggestions. Yes pea gravel is a good idea and we will try and use it to save on the self leveler.

Could the wrinkling be due to over working or drying too quick. Anyway what an achievement to go with all the previous ones. Well done all of you. Its coming 👍🏼

I suspect it’s onlong those lines. Will talk to Ardex today and see what they think caused it.