… is all a kitchen table needs and who said romance was dead.

It’s still too cold to do much down the house, hence lack of posts. Last week it got down to -4F/-20C and there was a sheet of ice on our wooden floor! This week though is a lot warmer but the temperatures are still too low to epoxy or paint etc. so I try and do some work at home, plus it’s a lot nicer to work in our cosy apartment 🙂 At home I can fill all the dents and holes etc. with System Three epoxy as it looks like the door has had a couple of different style locks and taken a good lot of beating over the years with at least one good kicking and crowbar attack 🙁

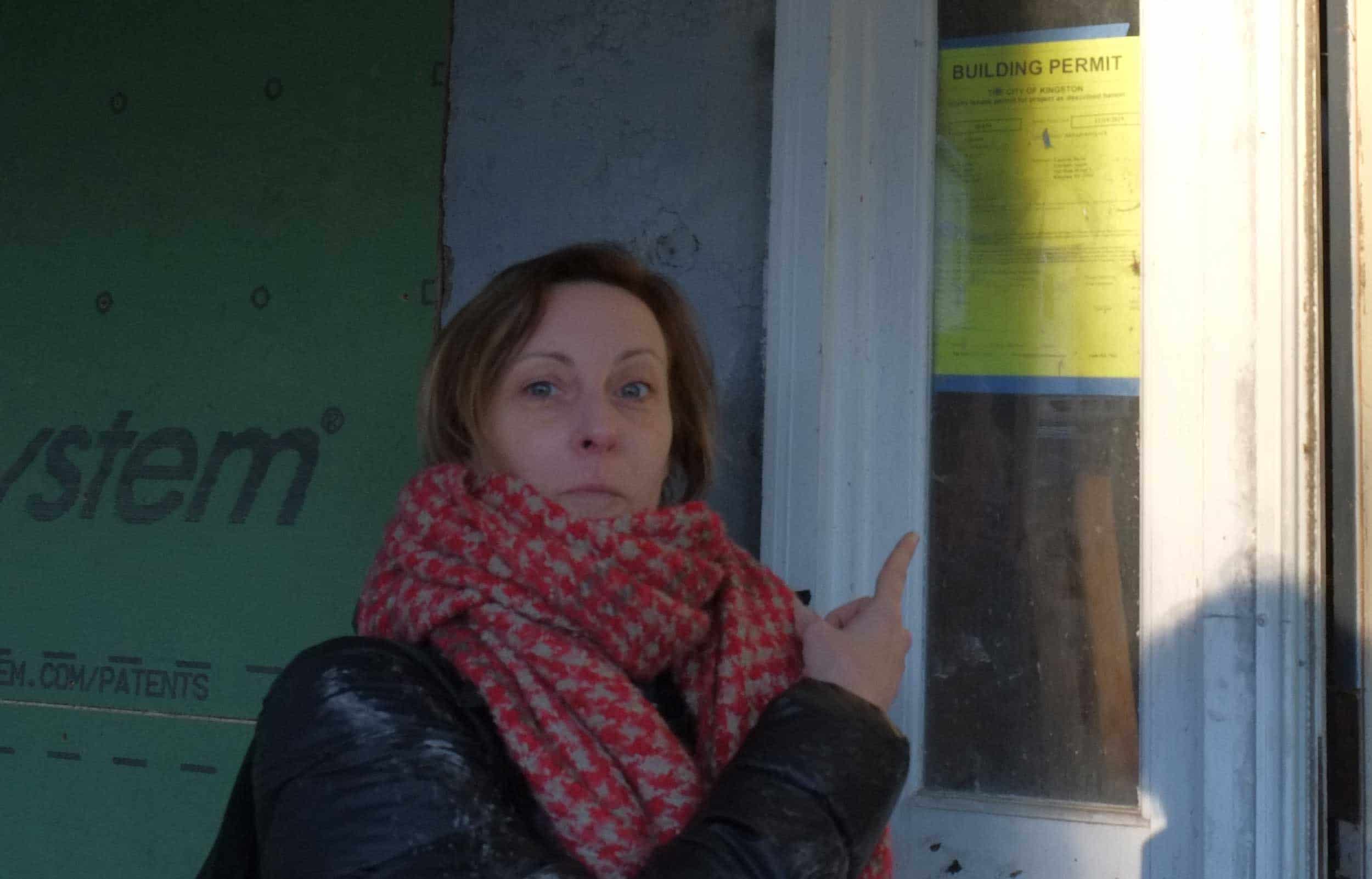

Current project is to replace the old and broken mortise lock with a high quality mortise lock. There are plenty of options out there but we eventually went for a Baldwin mortise kit which comes with everything, the actual lock, strike plates, door knobs, etc. etc. Not cheap though.

My Stanley Sweetheart which my brother Ian brought me for Christmas was perfect for the job. The door already had a mortise in it, but the new lock required I widen it and extend it by a couple of inches. Next step is to rebate the side of the door so the lock plate is recessed, but I’ll use a router for that.