We’ve almost finished our new ground floor front door. I did think we could make it in three weeks, but it’s probably been nine weeks already, not continuously, just weekends and evenings and being interspersed with other projects. If we build another door it will be a lot simpler and quicker – you learn a lot on your first pass.

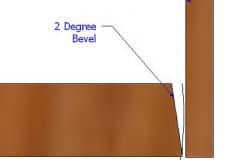

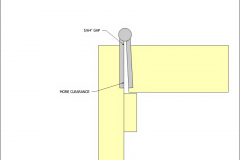

We’re almost at the point of painting the door and the last thing we have to do is to bevel both the lock and hinge sides of the door. The reason for beveling the lock side is to allow for a tighter fit of the door to the jamb when in the closed position and on the lock side it stops the hinges from banging into each other (called binding). Pictures below hopefully illustrate this.

The easist way to put a bevel on would be to run my track saw along both edges, set at say a 2° – 3° angle, however the door is too thick to cut through completely – our door comes in at 2 1/2″ thick which doesn’t seem thick, but it is, that said it does have a 1″ foam core to keep us cozy. Also the saw tracks are pretty wide and once you add the trim to door (which is raised) you can’t do this – I made this mistake on the last door.

So how to add the bevel? I thought of using a hand plane which I’m sure would have worked but it would have been tricky to get a consistent angle, then we borrowed an electric hand planer from Don, but same issue with the angle. After spending so much time on making the door I didn’t want to mess it up right at the end.

Searching, I found out about a tool, sadly no longer made, which was made for door beveling, the Porta Planer 126, made by Porter Cable. As an aside I always thought that Porter(a) Cable meant PORTAble electric tool on a CABLE but if you follow the above link the company was created by Mrs Porter and Mrs Cable. I started looking for a 126, which seems to be an appreciating classic, but all the ones on ebay were a few hundred dollars and then I came across one being sold locally by the Kingston Boat Building School, for $80.

You’ll have to agree it’s a beauty of a tool, it’s quite the work of art and I read somewhere that the Rockwell engineers who designed this may well have been designing exotic jet planes or rockets. This one is probably at least 40 years and likely a lot older. The bevel angle drawn on the door in the last picture is just to let me know which side to put the bevel and actual bevel will be a lot less.

The only downside with this tool is that spare parts are no longer in production, especially the cutter head. The cutter heads do turn up on ebay every now and then but they sell for about $150. However, this tool has a trick up it’s sleeve – you can sharpen the blade yourself on site!!!! Notice the accessories? They’re the parts to sharpen the spiral cutting blade with the small round object being the grinding stone. Now who builds tools like this any more? I know my friend Win would have loved this.

That’s a great bit of kit.

Yes it is pretty cool. I haven’t perfected using it but we’ll get there