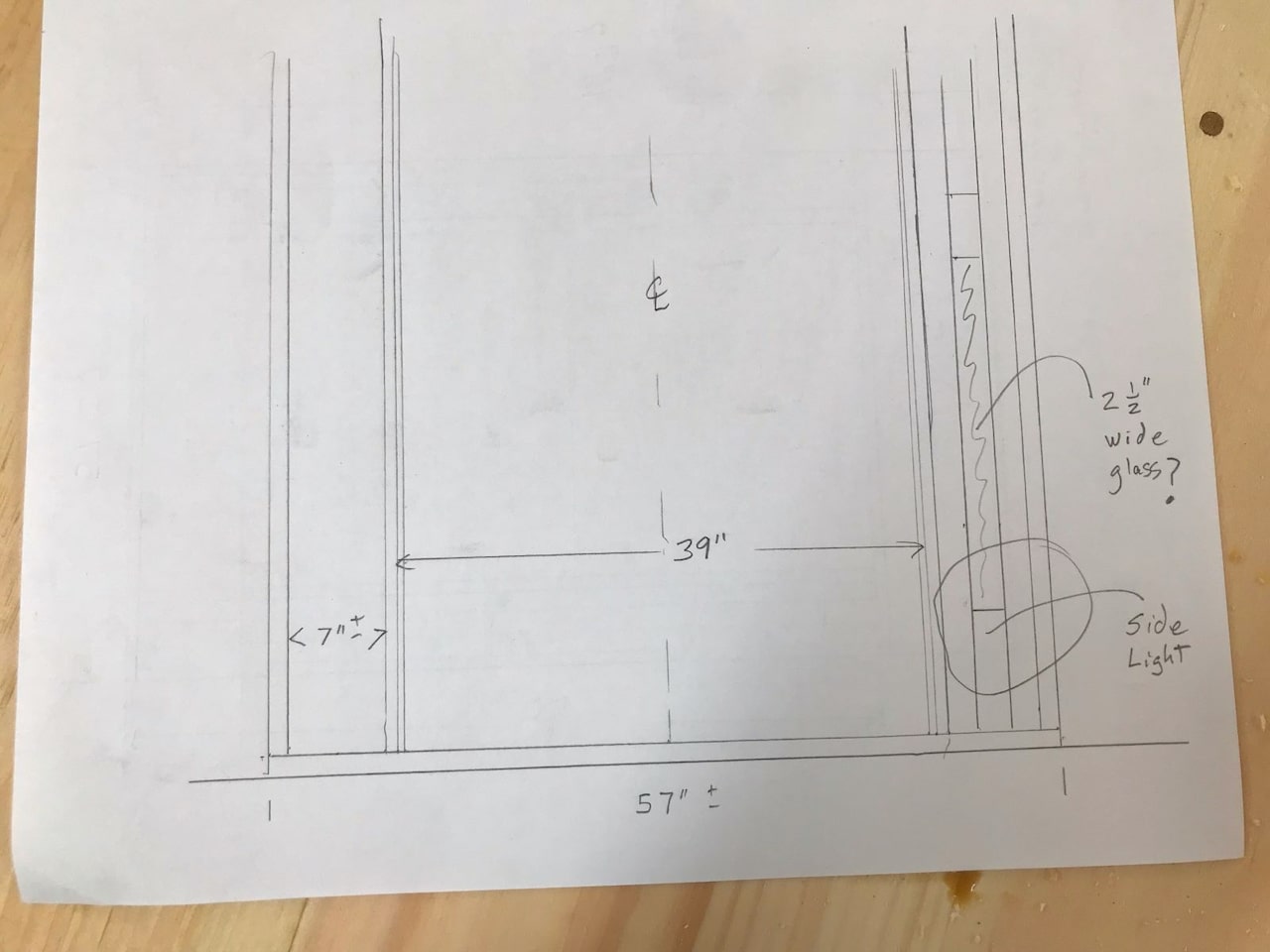

Back again to the front door. We’re trying to get the opening correct for the door we restored a few years ago. The current door (circa 70s, 80s) doesn’t align vertically with the door above it, so our aim is to shift the door a bit to the left so it does – we believe the original door was centered. The new door is 3″ wider than the current door but we will still hope to have side windows to let in a bit more light.

We decided to enlist the help of the talented Josh Finn to build us a new door frame and to install the door. Josh’s initial sketch (below) shows that with the current door opening the side windows would only be 2.5″ wide which isn’t very much so I’ve been working on making the door way gap a little larger. As it turned out the pressure treated wood I added to either side of the newly extended wall wasn’t square – not sure how that happened, user error or maybe the mortar pushed it out, anyway it was bugging me so I ripped both of them off, which in effect undid a couple of days work – bummer but I want to get it right.

I then got back to my least favourite task of chiseling and grinding away at the wall, annoying as we had just rebuilt one side of the wall. Grinding away the lime mortar is easy as it still reasonably soft (lime mortar takes weeks to cure), but the rocks are really tough to grind down. From the pictures there doesn’t look like there are many rocks, but if you scroll to the bottom, you can see them after I sprayed the lime with water. I estimate 12 hours to finish the grinding. It’s also very messy, with stuff going everywhere and clouds of dust.

First pass of the grinding removed 1″ – 2″ of the new wall and then I decided to remove another 1″ – 2″ but this time, not extending to the outside so the pressure treated wooden door jams aren’t visible from the outside. You can see the the laser line I’m trying to keep to in the photos below.

Hopefully now, our side windows will be at least 4″ wide which I think is reasonable.

Because the ground walls aren’t perfect, we sprayed them with lime mortar and then I plan to grind the surface flat so the door jams fits snugly. Lime mortar is fast to grind away, just very messy. While we’re spraying mortar we also started to spray the few remaining untreated walls in the house. There was a bit of prep as we had to remove all the lose stuff which covered most of the surface.