During this winter we’ll start making some sash windows for the ground floor. In total we have eight to make. This is a pretty big job as it’s not just the window sashes that have to be made but also the window bucks and the window cases/sash boxes that contain the pulleys and weights etc. We’ll do a trail run first to see how it goes and if that proves too hard then we’ll save up and pay someone.

We’ll use cheap pine for the first one we make as we’re bound to make mistakes and we don’t want to waste expensive wood. The final windows will be made out of a thermally modified wood. This heat treated wood is rot resistant and dimensionally stable (won’t warp much), it’s permanently resistant to water and it’s looks beautiful (think mahogany). The only downside is the cost, $8 – $10 a board foot but luckily I found Paul on craigslist who was selling some left over project wood for $4 a board foot. This is the second lot we’ve bought from Paul which he kindly delivered.

Initially we had planned to use Accoya, which is another long lasting wood and possibly better than thermally modified wood, for the windows, however, it’s not that easy to get hold of it or as beautiful, that said we will probably use Accoya for the remaining windows in the house.

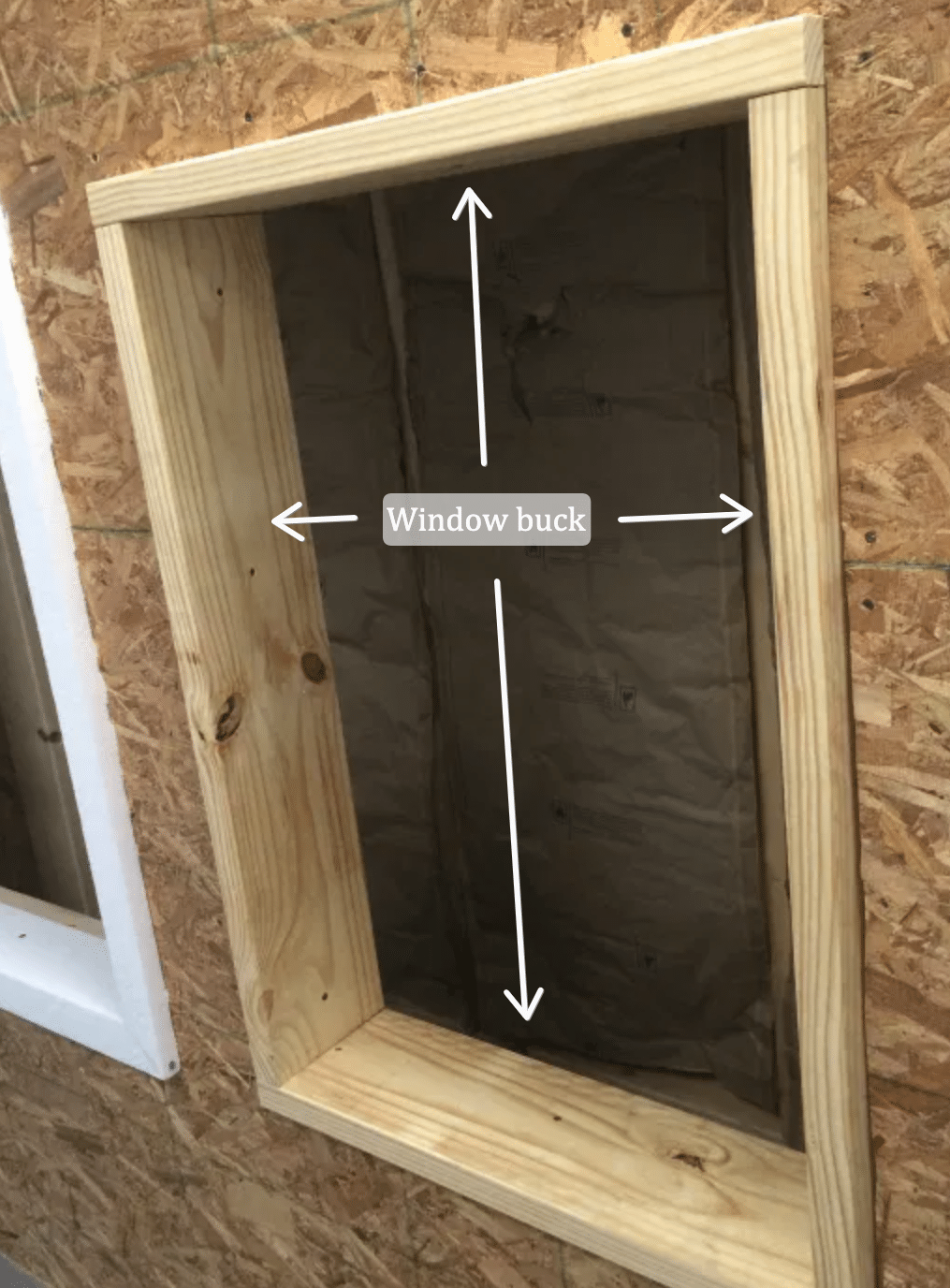

So the first thing we have do is to make the window bucks out of pressure treated wood. These aren’t visible when the window is complete so they don’t have to be fancy. We’ve cut all the wood to size and now they’re ready to be assembled for which we’ll be using the Dowel Max which looks a lovely bit of kit.

Never a dull moment. Merry Christmas and happy new year. Chris & Claire

I don’t know, windows seem pretty dull!!!! Happy Christmas and New Year to you both and I’ll give you a bell over the festive period